Disclaimer: This post contains affiliate links to products I personally use and recommend. I receive a small fee on qualifying purchases you make, at no additional cost to you.

Have you ever wondered how to oil a sewing machine?

Where does the oil go?

How often should it be oiled?

What kind of oil should you use?

I have taken the time and done the research to guide you through this simple process for oiling your sewing machine.

If you have your manual, you should read up on the maintenance of your machine. It will tell you all the important information on how to keep your machine in tip top shape.

It will also have instructions on how to oil your specific machine.

They all vary slightly as to where the oil ports are and which parts require oil.

If you have an older sewing machine like I do you can most likely find a PDF version of the manual online by doing a google search. I found the manual for my Singer 99k online. I also have a Baby Lock Jubilant and have the original manual.

For the most part, though, you can make quick work of this process by following this guide. I’ll teach you the fundamentals of how to oil any machine with moving parts.

Once you’ve reviewed your manual for the requirements for your machine, you should have your bottle of oil and machine out and ready to go.

HOW TO OIL ANY SEWING MACHINE

1. Unplug your machine and practice all safety recommendations in your manual! You should never try to work on your sewing machine while it’s plugged in. Safety always comes first.

2. Look for any oiling ports on an older machine and put a drop or two into each one. Oil ports on older machines will most likely be a small hole. It can be in the top of the machine like on an old singer, or at a pivot on an arm underneath.

Either way, if there is a small hole near a gear or spindle, chances are its an oil port. Even if it’s not, you will NOT hurt anything by putting a drop or two of oil in it!

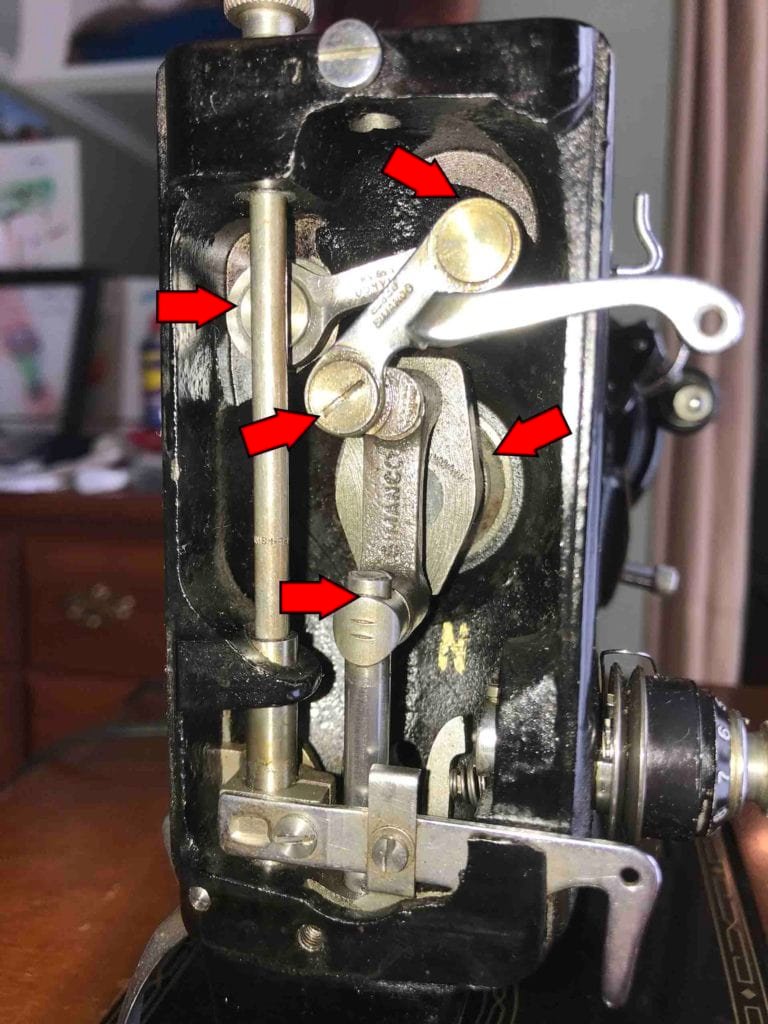

3. Remove all the covers and plates and look for more oiling ports. (My Singer 99K had somewhere near 30-40 oil ports!) Be very careful when doing this. Keep track of the screws and only do one section at a time so you don’t get them mixed up.

Older machines have more oil ports and required more cleaning and maintenance than newer machines. Manufacturers wanted to simplify the maintenance as much as possible.

4. Not all points that require oil will have a port. Find any spots where metal contacts metal and put a drop of oil. If there is a point where two pieces of metal are in contact and move, they need oil.

5. When finished oiling turn the flywheel by hand a few times to spread the oil around. You can do this as you’re placing the oil as well. I turned the fly wheel after every few oil points to make sure the oil got spread before it dripped out of the port.

Not all machines have as many oil ports and most newer machines have much fewer than this. Modern machines are made with materials that are naturally able to withstand the constant friction without requiring regular oiling.

I have a serger that only has 2 oil points.

How frequently should you oil?

Oiling frequency will be determined by your sewing frequency. Common practice in the sewing industry is every 8 hours of sewing time. This does not include time where the machine sits idle while you pin, or other tasks. Only time where the machine is running counts.

You should use a regular sewing machine oil. You should never use WD-40 as a lubricant as it contains a solvent that can displace good oil. It’s ok for cleaning, but never rely on it to lubricate your machine.

It can’t handle the high speeds a sewing machine reaches.

You should only use sewing machine oil. I recommend the one with a long spout for reaching those hard to reach places.

If you sew infrequently, you should consider oiling whenever you get your machine out. If you let it sit for long periods of time the oil can evaporate. I recommend oiling before you turn it on. Even if it doesn’t need it, it won’t hurt anything.

When storing your machine you should make sure it’s well oiled. If you’ve been sewing for a while, and haven’t oiled lately, just give a drop or two at each oil port to ensure its well protected during storage.

If you’re new to the blog, you should definitely check out my last post. You can also read my post about Men Who Sew.

Dan, Can you please come and oil my machine? Thank you! Love mom <3

Great idea. So many new machines state ‘no oil needed, service by dealer only’. I honestly like cleaning and pulsing my machines. It’s therapeutic. If they’re working well, hopefully my sewing is better.

Thank you